Why We Make PVD Color Coating on Stainless Steel Sheet Surface

Mar 02, 2024

PVD (Physical Vapor Deposition) color coating is a treatment method used to apply thin layers of decorative or functional coatings to various materials, such as metals, plastics, ceramics, and glass. The process involves the deposition of vaporized materials onto the substrate, resulting in a durable, thin-film coating with enhanced properties.

The advantages of PVD color coating include:

1.Enhanced Durability: PVD coatings are highly resistant to wear, abrasion, and corrosion, making them ideal for applications that require long-lasting protection or decorative finishes. The deposited coatings are typically harder than the base material, providing improved toughness and resistance to scratches.

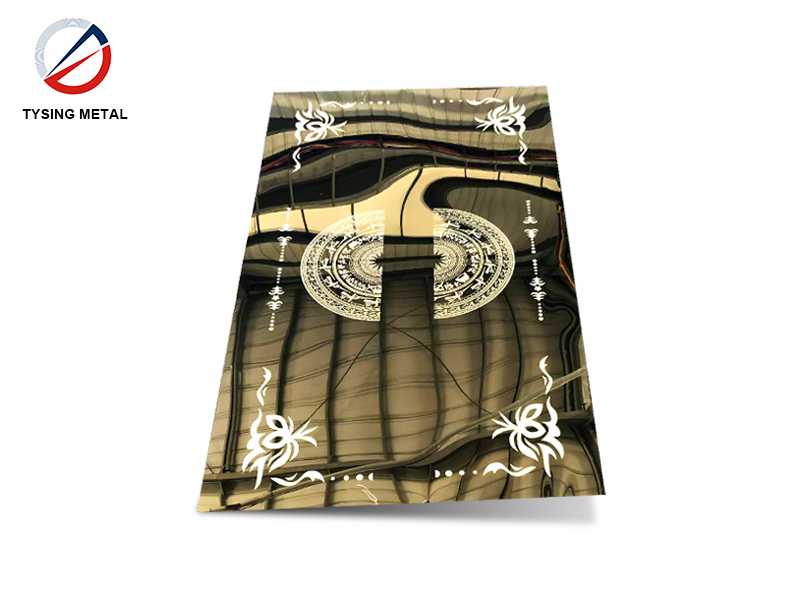

2.Wide Range of Colors: PVD color coating enables the application of a broad spectrum of colors and finishes, ranging from metallic shades to mattes and even custom designs. This allows for greater design flexibility and the ability to achieve unique aesthetic effects.It can be used on Mirror Finish or Brushed Finish.Color can be Bronze,Blue,Black,Champagne,Nickel Silver,Gold,Rose Gold,etc.The very polular surface is:Mirror Gold Finish stainless Steel sheet,Hairline Gold color,Brush Gold,Hairline Rose Gold.

3.Environmentally Friendly: PVD color coating is considered an environmentally friendly process compared to traditional plating methods. It does not involve the use of harmful chemicals or produce hazardous waste and is typically a low-temperature process, reducing energy consumption and greenhouse gas emissions.

4.Adhesion and Uniformity: PVD coatings exhibit excellent adhesion to the substrate material, ensuring long-term stability and preventing delamination or peeling. The deposition process also provides uniform coverage, allowing for consistent color and finish across complex-shaped objects or intricate details.

5.Improved Surface Hardness: PVD coatings can significantly increase the surface hardness of the treated material, enhancing its resistance to wear, scratching, and marring. This makes PVD color-coated products suitable for applications where durability is essential, such as high-traffic areas, automotive components, or jewelry.

6.Easy Maintenance: PVD-coated surfaces are relatively easy to clean and maintain. The coatings are typically smooth, dense, and non-porous, preventing dirt, grease, or stains from penetrating the surface, making them easier to wipe or rinse off.

7.Versatile Applications: PVD color coating finds applications in various industries, including automotive, architecture, aerospace, electronics, and consumer goods. It can be used for decorative purposes, improving product aesthetics, as well as functional applications like providing corrosion resistance, thermal protection, or electrical insulation.

Feedback from Elevator Cabin Factory Client of Gold Etching Stainless Steel Sheet

Jun 04, 2024

Feedback from Elevator Cabin Factory Client of Gold Etching Stainless Steel Sheet

Jun 04, 2024

Super Mirror Finish 304 Stainless Steel Sheet

Oct 21, 2023

Super Mirror Finish 304 Stainless Steel Sheet

Oct 21, 2023

Water Ripple Stainless Steel Ceiling Panel

May 13, 2023

Water Ripple Stainless Steel Ceiling Panel

May 13, 2023

How to Make Etching Finish Stainless Steel Sheet

Nov 16, 2022

How to Make Etching Finish Stainless Steel Sheet

Nov 16, 2022

Test of 201 J2 Material

Mar 17, 2023

Test of 201 J2 Material

Mar 17, 2023

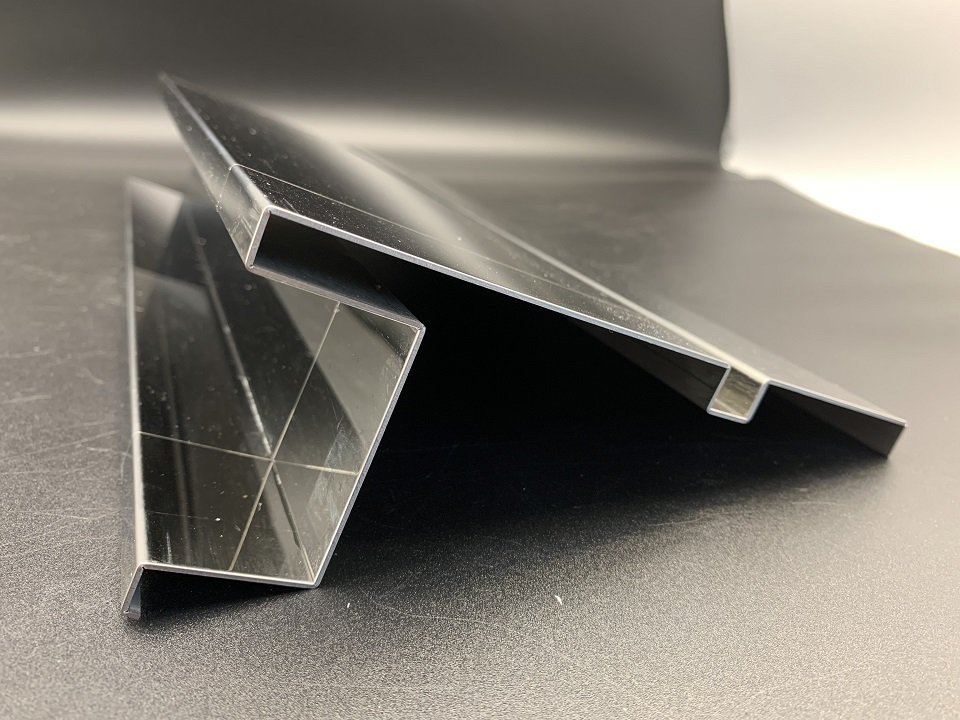

Anti-Scratch Stainless Steel Sheet

Apr 08, 2023

Anti-Scratch Stainless Steel Sheet

Apr 08, 2023