Sign up to get the latest product announcement and offer.

This etching pattern is a classic design of the elevator door and cabin.It use etching process and #8 mirror polishing finishing.It is very popular among users in the Middle East and Southeast Asian countries,such as Qatar,the United Arab Emirates,Thailand and Vietnam.

Grade: :

201/304/316Surface: :

Etching FinishSize: :

1219*2438mm,1219*3048mm or customizedColor :

PVD GoldenLead Time: :

7-25 days after depositMOQ :

50pcsColor Etching Stainless Steel Elevator Sheet

Stainless Steel Etching Sheet have different patterns and colors,and can be customized,which enriches the choices of elevator decoration.Because of the characteristics of stainless steel,it can be corrosion-resistant and high-strength.It has a long service life when used on elevators,is easy to maintain,and reduces the cost of use.Moreover,stainless steel is easy to process,and can be bent and welded into different sizes and shapes,which is convenient for the production of elevators.

| Name | Color Etching Stainless Steel Elevator Sheet |

| Material Grade | Stainless Steel 201/304/316 |

| Thickness | 0.5-3.0mm |

| Size | 1000*2000mm 1219*2240mm,1219*2438mm,1500*3000mm |

| Color | Gold,Rose Gold,Bronze,Black,Champagne,White Gold,Brass,Etc |

| MOQ | 30pcs |

| Packing | PVC+ waterproof paper + strong sea-worthy wooden package |

| Payment Term | T/T, L/C at sight |

|

Chemical composition and mechanical properties of stainless steel coils |

|||||||||

|

Grade |

Chemical Composition (%) |

Mechanieal Performece |

|||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Hardness |

|

|

201 |

≤0.15 |

≤1.00 |

5.5/7.5 |

≤0.060 |

≤0.030 |

3.5/5.5 |

16.0/18.0 |

- |

HB≤241,HRB≤100, HV≤240 |

|

304 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

8.0/11.0 |

18.00/20.00 |

- |

HB≤187,HRB≤90,HV≤200 |

|

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

10.00/14.00 |

16.0/18.0 |

2.00/3.00 |

HB≤187, HRB≤90 HV≤200 |

|

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

10.00/14.00 |

16.0/18.0 |

2.00/3.00 |

HB≤187, HRB≤90 HV≤200 |

|

410 |

≤0.15 |

≤1.00 |

≤1.25 |

≤0.060 |

≤0.030 |

≤0.060 |

11.5/13.5 |

- |

HB≤183, HRB≤88 HV≤200 |

|

430 |

≤0.12 |

≤1.00 |

≤1.25 |

≤0.040 |

≤0.03 |

- |

16.00/18.00 |

- |

HB≤183, HRB≤88 HV≤200 |

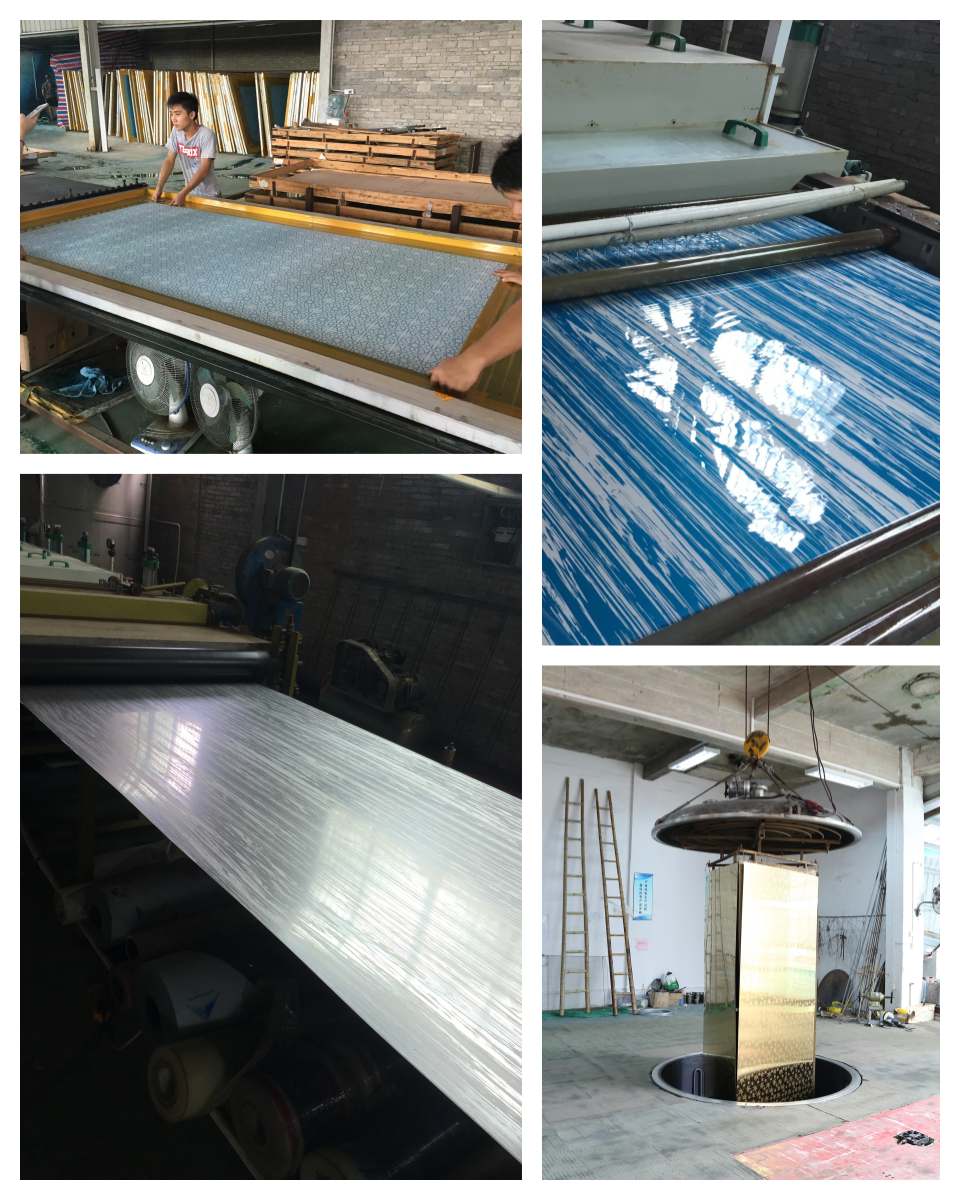

We have more than 300 kinds of etching molds for customers to choose.As long as it is the etching mold we have, there is no extra mold fee.

If the customer needs a customized etching pattern,we can make a corresponding etching mold, and then manufacture the desired pattern.

Although the standard size of the total pattern is 4ft*8ft and 4ft*10ft. But please don't worry about specs restricting your elevator interior,not only that,most patterns of our elevator etched sheets are adjustable and customized.All of our Color Etching Stainless Steel are available in various colors (gold,black,silver,rose gold,bronze,wine red, etc.) for your choice,please consult us for details.

The Stainless Steel Elevator Panels etched finish is chemically etched on the surface of stainless steel to produce various required patterns.The pre-prcess sheet can be 8K mirror finish,hairline finish and sandblasting finish.After etching,the etching sheet surface can be further processed.Stainless steel etched sheets can be used for complex processes such as partial processing,brush,color coating,and partial titanium plating.The stainless steel etched sheet is light and dark patterns and brilliant colors.

Stainless Steel Appliances

Etched stainless steel sheets have different patterns and colors,and can be customized,which enriches the choices of Stainless Steel Elevator decoration.Because of the characteristics of stainless steel,it can be corrosion-resistant and high-strength.It has a long service life when used on elevators,is easy to maintain,and reduces the cost of use.Moreover,stainless steel is easy to process,and can be bent and welded into different sizes and shapes,which is convenient for the production of Stainless Steel Elevator Cabin.

Stainless Steel Etching Process

The two printing processes are as follows:

Exposure method: the project is based on the pattern to prepare the material size - material preparation - material cleaning - drying → film or coating → drying → exposure → development → drying - etching → stripping → OK

Screen printing method: cutting material → cleaning sheet (stainless steel other metal materials) → screen printing → etching → stripping → OK

FAQ:

1. How to get quotation?

Confirm the stainless steel grade 201/304/316/43.

The stainless steel sheet size,standard size is 1219*2438mm

The thickness 03-3.0mm

The quantity

The surface finish and color.

Better let us know what is the usage.

Then we can know quote best price for you.

2. What is the Minimal Order Quantity(MOQ)?

Usually our MOQ is 50pcs.If have special request,we can check the quantity together.

3. Can you OEM or ODM?

Yes we can.We can make stainless steel sheet following you sample.And make right package for you.

4. What is your lead time?

7 Days for sample.

25-30 Days for bulk production.

Tags :