Sign up to get the latest product announcement and offer.

We use PVD coating to make stainless steel sheet in Bronze color.We can make color following clients's sample,and ensure the color is same in same order.

Grade: :

201 304 316Surface: :

Mirror finishSize: :

1219*2438mm,1219*3048mm or customizedColor :

SilverLead Time: :

7-25 days after depositPVD Coating Bronze mirror finish stainless steel sheet is ususally in 0.8mm,1.0mm or 1.2mm thick.The size is 1219*2438mm,1219*3048mm or to be customized.

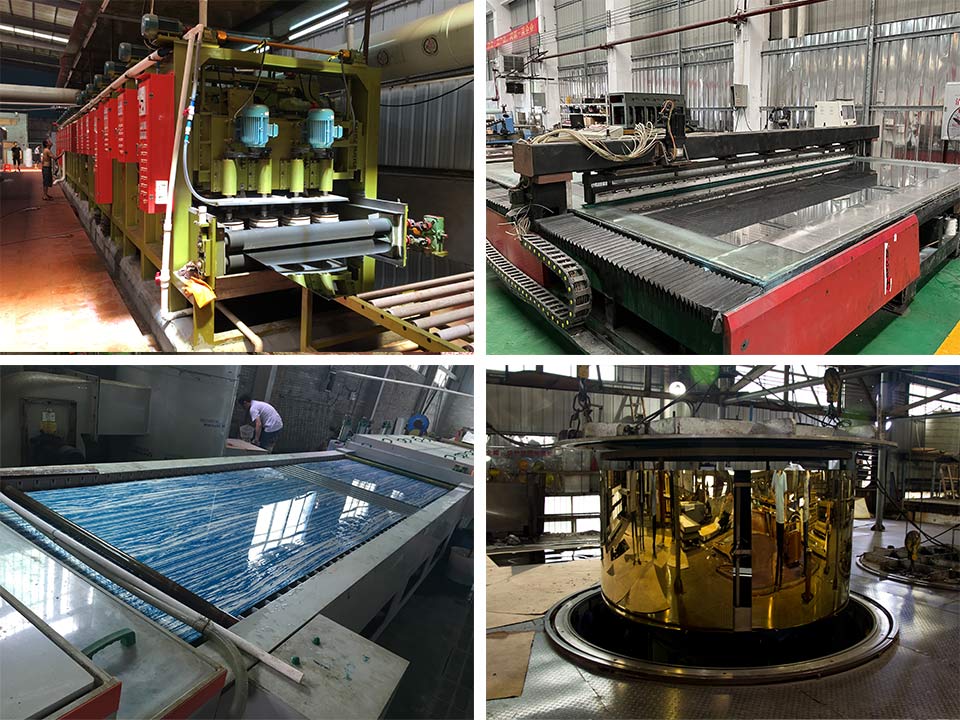

#8 Mirror has a high degree of reflectivity and a mirror-like appearance. Stainless steel were polished by 13 group polished machines, the resulting finish is mirror-like.

|

Product Name |

PVD Coating Bronze mirror finish stainless steel sheet |

|

Thickness |

0.5-1.5mm or as required |

|

Size |

1000*2000mm 1219*2438mm 1219*3048mm or be customized. |

|

Standard |

AISI, JIS, GB, etc |

|

Surface Finishing |

Mirror Polishing finish |

|

Material |

201/304/316/430/etc |

|

Application |

Ceiling,Cladding,Wall Facade |

|

MOQ |

50 sheets |

|

Lead Time |

Within 15~30 days after receiving deposit |

|

Packing |

Standard Export Seaworthy Wooden Package/or as required |

|

Capacity |

50,000 PCS Production Capability/Month |

Mirror finish is one of the most basic and commonly used surfaces of stainless steel sheet,whether it is applied directly to engineering projects or as one of the processes for further process.On the basis of the mirror surface,PVD color coating,etching and other surface treatments can also be done.

We put the high-quality stainless steel sheet into the polishing machine, then will have a series of polishing and chemical substances to remove the surface roughness of the material and improve the brightness, so as to achieve the mirror effect. After cleaning and drying, the mirror surface treatment is completed.Then we do inspection of the stainless steel sheet to make sure the mirror finish is perfect.Then can put on protect film and make package.

APPLICATION

Stainless steel sheet has excellent properties such as corrosion resistance,and easy processing.

Through the combination of different surfaces, such as mirror and brushed, it creates a unique light and shadow outlook.

It is widely used in the fields of construction,kitchen utensils,and automobile exhaust systems,and it also has aesthetic effects.

Differences of 201/304/316/430

201: poor corrosion resistance, widely used as a cheap substitute for 300 series in China.

304: it is the most commonly used. products such as :corrosion-resistant containers,tableware, furniture, railings, medical equipment.

316: the second most widely used steel type is mainly used in the food industry,clocks and jewelry,pharmaceutical industry and surgical equipment.

430: Ferritic stainless steel, for decoration, for example for car accessories.

Good moldability, but poor temperature resistance and corrosion resistance.

Mirror polishing finish has high requirements for stainless steel materials,the surface needs to be flat and dense. If the material is not good, problems such as sand hole or grain will appear, and the surface will not be particularly smooth, and defects can be seen.

We also provide mirror stainless steel sheet metal processing,such as laser cutting,bending, welding and other CNC services.

FAQ

Q: What’s the difference between 6K grinding and 8K grinding?

A: The grinding speed. The speed of 6K is 600 turns/min, while 8K is 500 turns/min.

Q: How wide/long can be done? How about the range of sheets’ thickness you can do?

A: The widest sheet can be done is 1250mm, and 4.3m is the longest one we can do. The thickness is around 0.28-2.0mm.

Q: Is it any difference among different series? Would the cost be different?

A: Grinding grade 304 sheets would be easier than grade 201, but cost a quarter higher than grade 201.

Q: Is polishing related to thickness?

A: No, it’s just related to materials.

Q: What things will be added in during the grinding process?

A: Iron powder & acid.

Tags :